How the Mitsubishi Laser and other Precision Cutting Tools Help Create Safe Aircrafts

Aerospace companies Boeing, Northrop Grumman, Cessna mama and Bell Helicopter, build some of the world’s most sophisticated products. He’s products and not only intricate, they also are some of the world’s safest products. Getting this done requires exacting standards that are men both within the companies and through their supplier networks. Each company within the chain must deliver the same high quality level of products and service in order for the final product to be safe. Suppliers to this industry include companies like Mitsubishi who supplied the Mitsubishi laser which is a primary tool for cutting aircraft parts. The Mitsubishi laser, is a great example of a product that helps aircraft maintain their high levels of safety.

Aerospace companies build the airplanes, helicopters, rockets, spacecraft and other aircraft that companies, civilians, and the military use for transportation of humans, equipment and packages around the globe. Some aerospace companies provide the entire aircraft while others supply parts for the aircraft. Each is tasked with a difficult job which is to provide the fastest means of transportation available today, but also to deliver the safest means of transportation we have on the planet. All in all, they do a fantastic job, because the products that they manufacturer are very fast and extraordinarily safe.

Aerospace companies are able to deliver such high quality products because of the safety demands that are placed on their organizations and their products. These demands require a superior level of design and execution and the top aerospace companies are always ready to deliver.

At the heart of their being able to fulfill their mission, is the suppliers that provide the parts that meet the exacting standards of the aerospace industry. These parts must be able to perform in the harshest and most demanding conditions again and again. Their manufacture must be precise and consistent and assist aircrafts to meet the highest safety standards.

And for suppliers to do this consistently, they purchase the highest quality manufacturing tools for their businesses. Maniac craft parts used to be manufactured by hand, but the need for greater speed combined with high quality has caused manufacturers to lean exclusively on hi Precision machines. Very few manufacturers are able to produce these machines, but companies like Mitsubishi that manufacturer the Mitsubishi laser play a large part and aircraft safety.

Laser Cutters

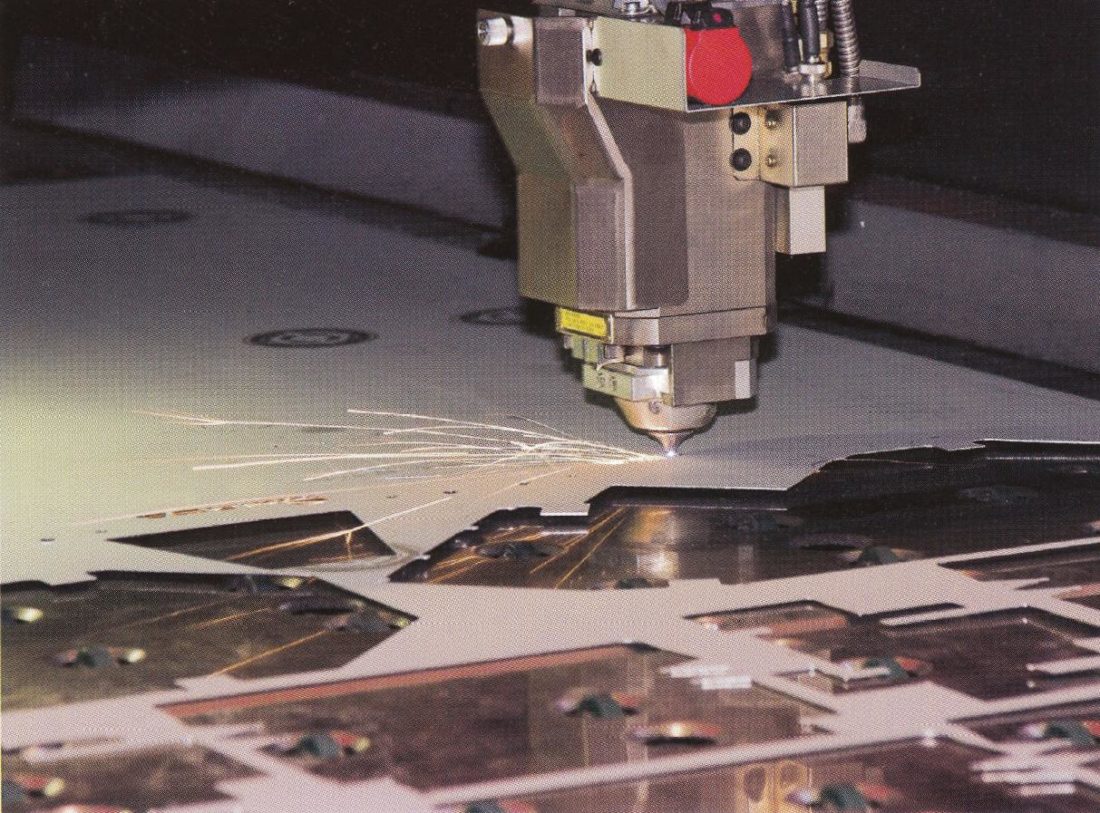

Laser cutters are used in manufacturing applications all types including manufacture of aircraft. They rely on high intensity lasers to cut materials and utilize optics and computer controls to direct the laser. The focused beam is directed at the material to be cut, which then either melts, burns, vaporizes away, or is blown away by a jet of gas. Laser cutters are used because they are fast, precise, and leave an edge with a high-quality surface finish. Typically, laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Mitsubishi Laser

In 1977 Mitsubishi introduced its first commercial laser cutting machine. The company found great success and dedicated itself to become a leader in the industry. The company has followed a fast track of innovation and new product design insuring that each component of its products meets with the highest quality standards and functions flawlessly in even the most demanding environment. The company now provides a complete range of laser cutters that are ideal for small job shops to complex automated laser cells.

These complex and high precision machines make parts that a critical to the safety of aircraft worldwide.